Radio-frequency identification (RFID) technology has the potential to revolutionise the fashion industry by improving supply chain management, inventory control, and consumer shopping experiences. RFID tags embedded in clothing items can provide real-time information about product location, tracking, and history, enabling retailers to make informed decisions about stock levels and sales. Additionally, RFID can enhance the in-store shopping experience for customers, allowing for faster and more convenient checkout, personalization, and the ability to access product information instantly.

Radio-Frequency Identification (RFID) is a technology that uses radio waves to communicate between a reader and an electronic tag attached to an object, allowing the object to be identified and tracked. The tag contains a microchip and an antenna, which send and receive signals from the reader. This technology is used in a variety of applications, including inventory control, supply chain management, and asset tracking, among others. Unlike barcodes, RFID tags do not need to be in the line of sight of the reader, making it possible to track items in real-time even when they are obscured.

There are several fashion companies that have implemented RFID technology to improve their operations and enhance the customer experience. Here are a few notable examples

Zara − The Spanish fashion retailer was one of the first companies in the industry to adopt RFID technology. They use RFID tags to track inventory levels in real-time, reducing out-of-stocks and increasing efficiency. RFID also allows them to quickly and accurately track the location of each item, making it easier to respond to changes in customer demand.

Levi Strauss & Co − The clothing manufacturer uses RFID to track the location of products throughout their supply chain, reducing the risk of lost or stolen items. RFID also helps them manage inventory levels and keep track of the product history, allowing them to make informed decisions about production and distribution.

Ralph Lauren − The luxury fashion brand uses RFID technology to improve the in-store shopping experience. Customers can quickly and easily find the products they are looking for, and RFID-enabled fitting rooms allow staff to instantly access product information and suggest additional items to complete the look.

H&M − The Swedish fast-fashion retailer uses RFID to improve their supply chain management and inventory control. RFID helps them track the movement of goods from the manufacturer to the store, providing real-time information about stock levels and enabling them to respond quickly to changes in demand.

Tommy Hilfiger − The American fashion brand has implemented RFID to improve their supply chain management and inventory control. RFID tags are placed on clothing items to track their movement through the supply chain and monitor stock levels in real-time. This helps the company reduce the risk of overstocking or stock shortages and make informed decisions about production and distribution.

Nike − The sportswear giant has been using RFID technology to enhance their retail operations and improve the customer experience. RFID-enabled fitting rooms allow customers to try on clothes and get recommendations for other items that might complement their look. RFID also helps Nike track inventory levels and monitor the movement of products through their supply chain, improving efficiency and reducing waste.

Burberry− The British luxury fashion brand uses RFID to improve inventory control and the customer experience. RFID tags are placed on clothing items to track their movement and monitor stock levels, allowing the company to respond quickly to changes in demand. RFID also enhances the in-store shopping experience, allowing customers to access product information and check availability instantly.

These are just a few examples of how fashion companies are using RFID to improve their operations and enhance the customer experience. The technology has the potential to revolutionize the industry, reducing costs, improving efficiency, and delivering a better shopping experience for customers.

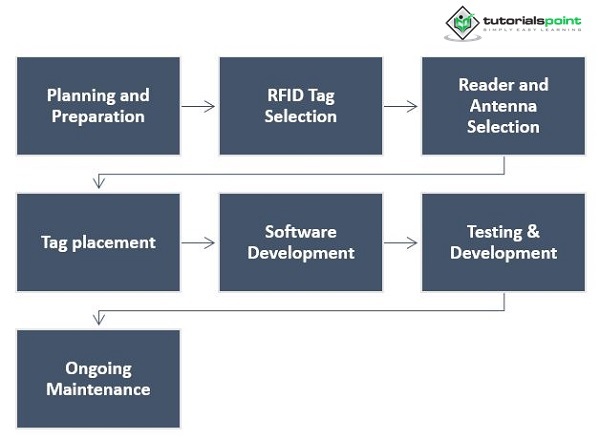

The process of implementing an RFID project in the fashion industry typically involves the following steps

Planning and preparation − This stage involves identifying the goals of the project and determining the scope, budget, and timeline. A detailed plan should be developed, outlining the objectives, milestones, and resources required.

RFID Tag Selection − The next step is to select the appropriate RFID tags for the project. Factors such as the frequency of the tags, the form factor, and the read range should be considered when making a decision.

Reader and Antenna Selection − Once the RFID tags have been selected, the next step is to choose the appropriate reader and antenna. The reader and antenna must be compatible with the tags, and their specifications should be reviewed to ensure they meet the needs of the project.

Tag placement − The RFID tags must be physically attached to the clothing items in a way that ensures they can be read accurately and consistently. The placement of the tags should be determined based on the specific requirements of the project.

Software Development − Custom software applications can be developed to manage the data collected by the RFID system, provide real-time information about inventory levels, and support decision-making processes.

Testing and Deployment − The RFID system should be thoroughly tested to ensure that it is working correctly and meets the requirements of the project. Once the testing is complete, the system can be deployed in stores or distribution centres.

Ongoing Maintenance − RFID systems require regular maintenance and upgrades to ensure they continue to function effectively. The system should be monitored, and any issues should be resolved promptly to ensure maximum performance and reliability.

This is a general overview of the RFID project process in the fashion industry. The exact steps and timeline will vary depending on the specific requirements of each project. Nevertheless, careful planning and execution are crucial to the success of an RFID implementation.

These are

Tagging − RFID tags are attached to each logistical unit and item in the fashion supply chain. The tags contain a unique identifier and other relevant information, such as the product type, size, and colour.

Packing and shipping − The tagged logistic units and items are packaged and shipped to distribution centres or warehouses.

Distribution and Warehousing − Upon arrival, the tagged items are received and stored in the warehouse. RFID readers and software are used to track the location and movement of the items within the warehouse.

Display, Sales, and Theft Prevention − When the tagged items reach the stores, they are placed on display for sale. RFID readers are used to track inventory levels in real-time and prevent theft by detecting when tagged items are removed from the store without being properly scanned at checkout.

Sales − When a customer purchases a tagged item, the RFID tag is deactivated at checkout to prevent theft. The sales information is recorded and used to update the inventory levels in real-time.

Overall, the RFID process helps fashion retailers improve supply chain efficiency, reduce loss and theft, and provide a better customer experience by enabling real-time inventory tracking and visibility throughout the entire supply chain.

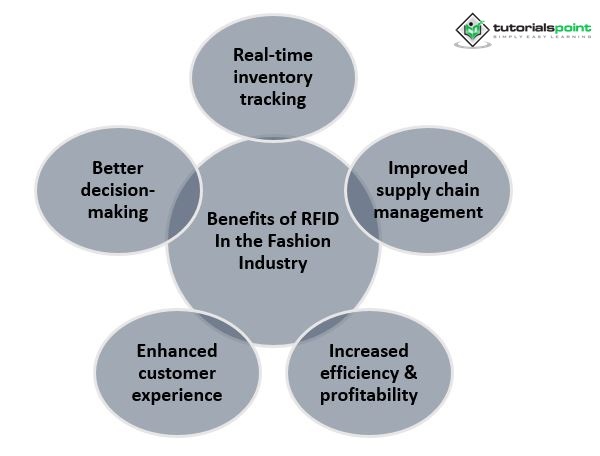

Here are the key benefits of RFID in the fashion industry, point-wise

Real-time inventory tracking − RFID technology can accurately track the movement of products from the manufacturer to the store and onto the customer, improving inventory management and reducing loss and theft.

Improved supply chain management − RFID can help retailers keep track of which products are popular and in demand, allowing them to quickly restock and meet customer demand.

Enhanced customer experience − RFID can provide customers with access to information about products and inventory levels, as well as enable features such as self-checkout and in-store navigation.

Increased efficiency and profitability − By streamlining processes and reducing inefficiencies, RFID has the potential to increase the efficiency and profitability of the fashion industry.

Better decision-making − With accurate and real-time data, RFID can provide valuable insights into customer preferences and behaviour, allowing retailers to make informed decisions about their products and operations.

The price and performance of RFID technology depend on various factors, including the type of tag used, the frequency of the RFID system, the range required, and the complexity of the software and hardware.

Low-frequency (LF) and high-frequency (HF) RFID systems are generally less expensive than ultra-high-frequency (UHF) systems, but they have a shorter read range and are less suitable for high-volume data collection. On the other hand, UHF systems have a longer read range and can handle high volumes of data collection, making them more suitable for large-scale RFID implementations in the fashion industry.

In terms of performance, RFID technology has come a long way in recent years and has become more affordable and accessible. Today, RFID tags can be small and durable, allowing them to be easily integrated into fashion products without affecting the design or appearance.

In conclusion, RFID technology has the potential to greatly impact and transform the fashion industry by providing real-time inventory tracking, improved supply chain management, an enhanced customer experience, increased efficiency and profitability, and better decision-making based on valuable insights. As the technology continues to advance and become more widely adopted, it is likely that we will see even more innovative and impactful applications of RFID in the fashion industry in the future.