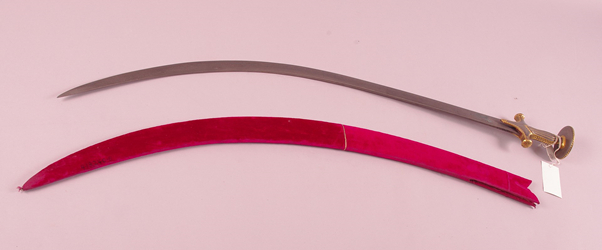

Tipu Sultan, the ruler of Mysore, who made Mysore a formidable power in the eighteenth century died in the fourth Anglo-Mysore war in 1799 in the battlefield with a sword in his hand. His sword was believed to be very strong, which indicates that the sword was made up of high-quality steel, called ‘wootz steel’, manufactured in the southern part of India. This steel of India even gained the attention of the western world they made a study of the production of this steel.

The production of the wootz steel included several steps and a specialized technique. Eventually, the British replaced this material in India by importing iron and steel from England. And new factories began to develop in India, which further deteriorated the condition of local craftsmen.

The sword of Tipu Sultan which he used in the Anglo-Mysore wars, was kept in the museum of England for many years as a valuable collection from India. It was believed to be so strong as it could even tear off the armors of rivals with its sharp edge. His sword was made from a special type of high carbonized steel, known as Wootz steel, popular in south.

The Sword of Tipu Sultan

Ezhuttukari at Malayalam Wikipedia, Public domain, via Wikimedia Commons

The word ‘wootz’ is an English word for the Kannada term ukku, hukku in Tamil and urukku in Malayalam language, meaning steel. The account made by Francis Buchanan gives us detailed information about the process of making wootz steel, which was common in southern India.

Wootz Steel

Mr McIntyre, CC BY-SA 4.0

They used to mix iron ore and charcoal together, and then put them into a clay pot. Later it was melted at fluctuating temperatures in furnaces and then smelters were used to produce steel blocks, which were used to make swords in India and Asia. The evidence of approximately a hundred furnaces has been found in Mysore. This wootz steel, even stole the attention of European scientists, for example, scientist Michael Faraday studied the properties of this steel for four years.

Nevertheless, the iron and steel industries began to end with the political expansion of the British and the import of these metals from Britain, which led to the gradual invisibility of ‘wootz steel’ by the middle of the nineteenth century. Now the Iron smiths were getting iron in bulk at a cheaper rate.

Although the manufacturing of iron and steel demanded concentrated techniques with skillful craftsmen, it was common practice in India. The family of craftsmen was involved in this process as men used to control the smelting temperatures and women used to do below works like pumping air to keep the charcoal burning.

However, by the middle of the nineteenth century, the production of Indian iron and steel started diminishing and smelters abandoned their furnaces. There were several reasons for the decline in the production of iron and steel in India.

The major reason for this decline was the implementation of the new forest law by the British government. Under this law, the government prohibited the entry of people in reserved forests, which meant the quality timber would be government property. And local smelters and craftsmen lost access to timber charcoal and iron ore, hence the raw material for the production of steel became inaccessible to them.

Even if they managed to enter these forests secretly to collect raw material but it was something that they could not continue for a longer period as a livelihood. As a result, they left this occupation and shifted to other means of livelihood.

Another reason was the high tax that iron smelters had to pay to the forest government for using furnaces even though the production was declining in India, hence this affected their income. This also forced them to abandon their furnaces and search for a new occupation.

Furthermore, the import of iron and steel from England enhanced problems by decreasing the demand for iron produced by local smelters. And now ironsmiths began to make their finished good with the European imported iron and steel. Simultaneously, these local smelters faced tough competition from Indian iron and steel factories.

All these factors somehow paved the way for local smelters to leave their furnaces and adopt other occupations in order to have a stable and sustainable livelihood.

During the eighteenth century, Indian iron and steel were considered to be of the greatest quality, and came to be called ‘’wootz steel’’. One such example of this wootz steel was the sword of Tipu Sultan, which was as strong as it could break down the hard armour with greater ease.

In fact, the high quality of iron and steel drew the attention of Europeans and made their research about the process of making it such hard and strong. Eventually, even after being of superior quality, the production of the wootz steel began to reduce and smelters opted for other occupations by abandoning their furnaces in the middle of the nineteenth century. Subsequently, the iron and steel produced by local Indian smelter were replaced by imported iron from Britain and manufactured by other newly emerging indigenous iron and steel factories in India.

Q1. What was the main reason for the Anglo-Mysore war?

Ans. The British territorial and commercial expansion in Mysore had to face a threat from the rulers of the region, Haider Ali and Tipu Sultan. The British formed alliance with the Nizams and the Marathas in order to subjugate Mysore and fought four wars, known as the Anglo-Mysore war.

Q2. Mention the chronology of all four Anglo-Mysore wars.

Ans.

First Anglo-Mysore war in 1767 CE to 1769CE.

Second Anglo-Mysore war in 1780 CE to 1784CE.

Third Anglo-Mysore war in 1790 CE to 1792 CE.

Fourth Anglo Mysore war in 1798 CE to 1799 CE.

Q3. Who was Francis Buchanan?

Ans. Francis Buchanan was a Scottish physician, who came to India and worked in Bengal Medical Service. He even worked as a surgeon of Lord Wellesely. He provided a detailed account of the territory under the East India Company. In a way, he contributed as a great zoologist, botanist, and ethnographer during his stay in India.

Q4. When did the colonial government pass the first forest law in India?

Ans. The first forest law, made by the British government, was passed in 1865 with the aim of taking control of forest produces rather than conserving them. The act was amended several times in successive years.

Q5. Which was the first iron and steel factory in India and when was it established?

Ans. TISCO; Tata Iron and Steel company was the first iron and steel factory in India and it was established in 1907 at Jamshedpur by Jamshedji Tata and Dorabji Tata.

Q6. Mention any three results of the Anglo-Mysore war.

Ans.

Most of the kingdom was divided between the British, Nizams, and the Marthas.

The remaining kingdom was handed over to the ruler of the Wodeyar dynasty from whom Haider Ali seized the power.

Now the ruler of Mysore was made to enter into a subsidiary alliance with the British.